Introduction

IoTstar 2025 is the latest version of ICP DAS’s IoT cloud management software. It integrates the original IoTstar software and service packages (Dashboard Service, Report Service, Bot Service, etc.) into a single product, streamlining IoTstar’s purchasing and installation process while making the system more intuitive and convenient to use. In addition to retaining all features and service packages from the previous version, IoTstar 2025 introduces several new user-centric functions and significantly enhances the overall user experience.

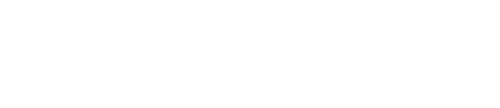

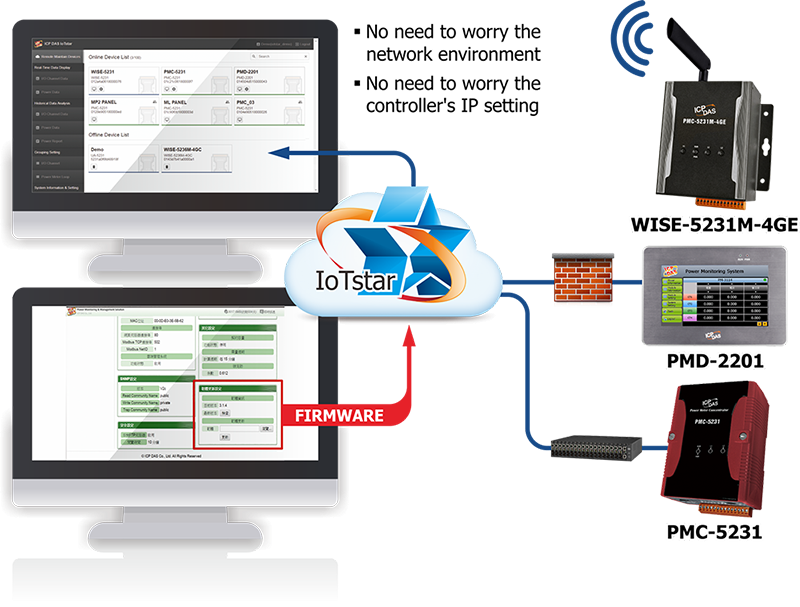

System Architecture

Features

Support Flexible Installation Environment for Quick IoT Cloud System Setup

- Public IoT Cloud Solution: IoTstar 2025 can be installed on VMs(virtual machine) within public cloud platforms such as Microsoft Azure, IBM Bluemix, Google Cloud, or Amazon AWS. This setup supports WISE, PMC, and PMD controllers while reducing the burden of maintaining the IoT cloud infrastructure.

- Private IoT Cloud Solution: If users are concerned about system operation or data storage environments, IoTstar 2025 can be installed on a private Windows PC (Windows 7/8/10 or Windows Server) to implement a private IoT cloud solution for WISE, PMC, and PMD controllers. This allows users to manage and control their own IoT cloud environment, ensuring complete oversight of operations.

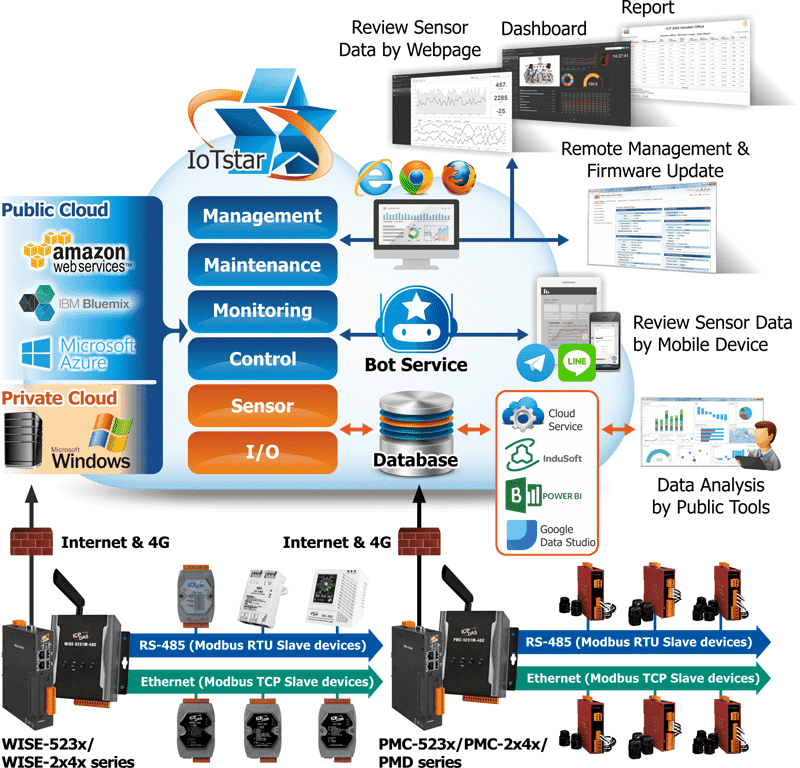

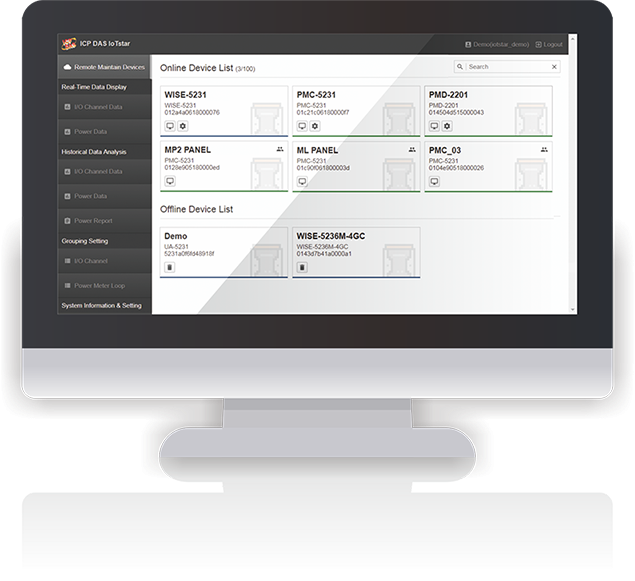

Controller Remote Access/Maintenance Service

Sensor Data Collection Service

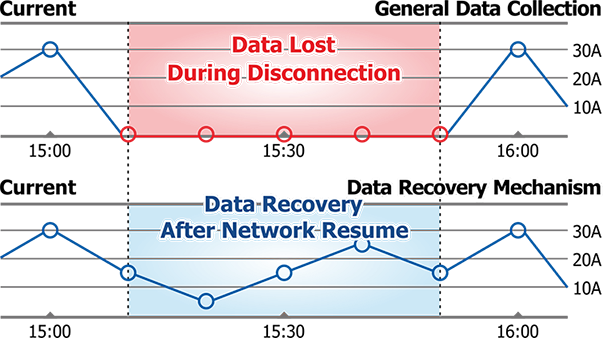

Sensor Data Recovery Mechanism

In typical cloud data collection processes, sensor data is gathered and sent to the cloud for storage in a database. However, if a network disconnection occurs, any data transmitted during that period may be lost. IoTstar 2025 addresses this issue with a built-in sensor data recovery mechanism. During a network disruption, WISE, PMC, or PMD controllers temporarily store all data on their SD cards. Once the network connection is restored, the stored data is automatically retransmitted to IoTstar 2025 and imported into the database, ensuring the completeness and integrity of historical sensor data.

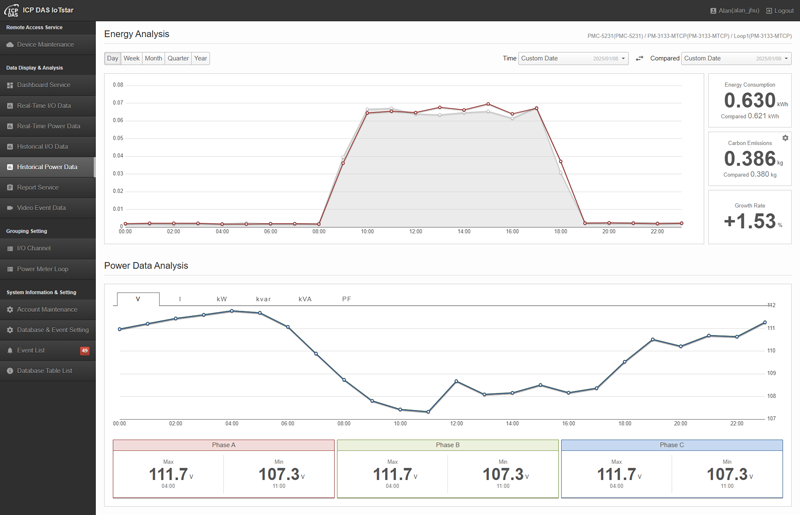

Sensor Data Visualization Service

IoTstar 2025 provides real-time and historical data queries for sensors and power meters connected to remote WISE/PMC/PMD controllers. It features dedicated power analysis pages that help users query and compare power consumption across different time periods, analyze usage trends, and identify potential energy-saving opportunities. At the same time, it helps reduce carbon footprints and contributes to environmental sustainability.

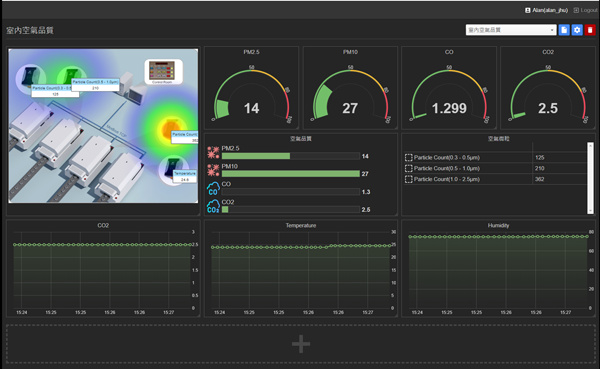

IoTstar Dashboard Service

IoTstar 2025 offers a dashboard editor and various widget components, enabling users to create customized dashboards for viewing real-time data from sensors or power meters connected to WISE, PMC, or PMD controllers. Users can quickly build the dashboards needed for IoT cloud monitoring, monitor sensor or power meter status in real-time, and interact with them directly.

- Offers a dashboard editor for users to easily customize specific dashboard pages.

- Includes a variety of built-in widgets to present sensor or power meter data in multiple formats.

- Displays real-time sensor or power meter data with the ability to modify output channel statuses.

- Provides a rich content widget (WYSIWYG editor), allowing users to edit widget content by importing HTML code, text, web pages, images, videos, and more.

- Supports 'Dark Mode' for improved visibility during nighttime use.

- Receives on-site snapshots or video files from controllers, enabling users to browse and review them through IoTstar (to send snapshots or videos, use WISE with an iCAM IP camera).

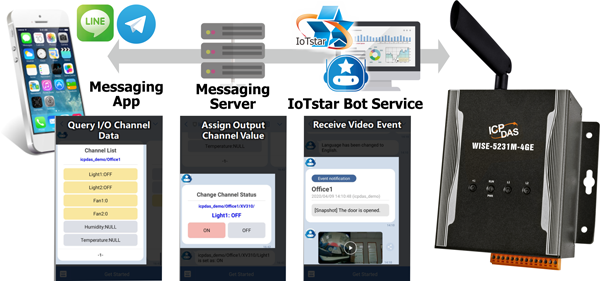

Bot Service on Controller by using Mobile Device

IoTstar 2025 offers a built-in chat room feature that allows users to interact with WISE, PMC, or PMD controllers via the LINE or Telegram app, providing a fast and convenient way to manage equipment. Unlike traditional chatbots that rely solely on text commands, it features a userfriendly interface with buttons and dialog menus for easy access to information. With this functionality, users can query real-time data from on-site I/O modules or power meters and adjust DO/AO channel values anytime, anywhere. Additionally, IoTstar 2025 can receive alarm events proactively sent by WISE, PMC, or PMD controllers and forward them to relevant LINE or Telegram users for real-time notifications. All alarm events are logged within IoTstar 2025, allowing users to review historical events using its event query feature.

Why IoTstar?

By using "IoTstar + WISE/PMC/PMD" solution, the users can quickly build the IoT cloud system to perform the remote maintenance on machine/Facility, as well as the remote monitoring of the environment. The "IoTstar + WISE/PMC/PMD" solution features the following benefits:| Items | Description | Benefits |

|---|---|---|

| System Installation | IoTstar can be flexibly installed on private PC system or on the VM of the Public Cloud platform. | Appropriate installation environment can be selected for the IoT system according to specific requirements such as "low cost" or "security". |

| Network Setting | Only need to set "Static IP" or "DDNS + Dynamic IP" for the IoTstar. | Dramatically reduce the complexity and cost in network setting. |

| System Implementation | The system settings of IoTstar/PMC/WISE/PMD can be completed through the web page interface. | No programming is required. The cost of system setting can be significantly reduced. |

| Controller Maintenance | Operator can perform remote maintenance for controllers via IoTstar at any time and any place. | Provide immediate maintenance on controllers, save the transportation cost when performing maintenance operations. |

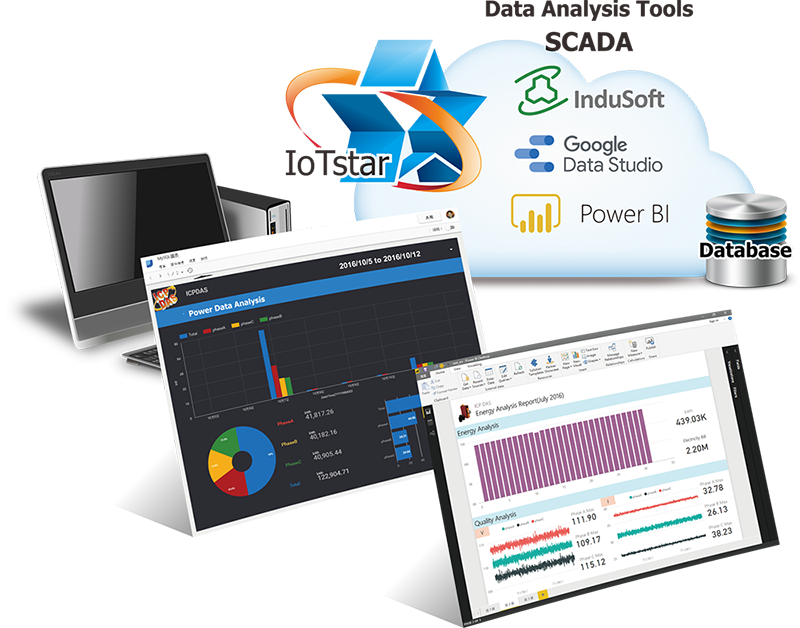

| Sensor Data Storage | IoTstar can import the Sensors data into database automatically , and work with the data analysis tools by SQL command. | The status of the monitored equipment can be known in advance to avoid possible damage. |

Cloud-based Power Monitoring Application for Factory

Using ICP DAS "IoTstar + PMC/PMD" solution, user can quickly build a cloud-based power monitoring system for factory. In the solution, PMC/PMD power meter concentrator can connect with ICP DAS power meters to collect, organize and record the power consumption information of the factory equipment. In addition to sending the collected power information back to IoTstar, PMC/PMD can also perform the power demand management for the equipment, monitor the operation of equipment to perform the corresponding actions, and immediately send LINE/Telegram/WeChat/Email/SMS alarm message according to the pre-set edge computing mechanism (IF-THEN-ELSE logic rules). After IoTstar receives the power information sent by PMC/PMD, it can provide services such as:"Controller Remote Access Service", "Sensor Data Collection Service", "Sensor Data Visualization Service", "Sensor Data Report Service" and "Bot Service with Mobile Phone", as well as the following benefits:- No need to write programs in the whole process, power information can be collected and stored in the cloud database automatcially.

- Through SQL Database interface, quickly integrate the IT system to understandthe trend and change of the power usage status of the factory equipment comprehensively.

- Perform remote monitoring and maintenance of the factory equipment, take corresponding actions proactively to ensure operational optimization.

- Provide status monitoring, system setting and firmware update for the PMC/PMD controllers from Cloud. It can reduce the time and cost of personnel travel due to performing maintenance of the equipment.

Cloud-based Environment Monitoring Application

Using ICP DAS "IoTstar + WISE" solution, user can quickly build a Cloud-based environment monitoring system. In the solution, WISE IIoT edge controller can connect with the Modbus TCP/RTU sensors to collect, organize and record the information of the environemnt. In addition to sending the collected environemnt information back to IoTstar, WISE can also monitor the operation of environemnt facilities to perform the corresponding actions, and immediately send LINE/Telegram/WeChat/Email/SMS alarm message according to the pre-set edge computing mechanism (IF-THEN-ELSE logic rules). After IoTstar receives the environemnt information sent by WISE, it can provide services such as: "Controller Remote Access Service", "Sensor Data Collection Service", "Sensor Data Visualization Service", "Sensor Data Report Service" and "Bot Service with Mobile Phone" services, as well as the following benefits:- No need to write programs in the whole process, environment information can be collected and stored in the cloud database automatcially.

- Through SQL Database interface, quickly integrate the IT system to understand the trend and change of the environment status comprehensively.

- Perform remote monitoring and maintenance of the environment facilities, take corresponding actions proactively to ensure operational optimization.

- Provide status monitoring, system setting and firmware update for the WISE controllers from Cloud. It can reduce the time and cost of personnel travel due to performing maintenance of the facilities.

Cloud-based Indoor Air Quality Monitoring Application

Using ICP DAS "IoTstar+WISE+DL/CL module" solution, user can quickly build a Cloud-based air quality monitoring system. In the solution, DL/CL series modules can be used to measure the concentration of aerosols in the air (Such as: PM2.5, PM1, PM10 and the number of particles (0.3μm, 0.5μm, 1μm, 2.5μm, 5μm, 10μm), as well as the fume concentrations related to human health (Such as: CO/CO2/HCHO/NH3/H2S/TVOC), and then transmit the measurement of air quality information to WISE IIoT edge controller. WISE is used to collect the air quality information from DL/CL modules and send back the information to the IoTstar. To response to any unusual situation and to maintain the safety of personnel in the field, WISE also can take the corresponding actions (Such as: turn on the exhaust fan and warning light, activate the access control equipment, send LINE/Telegram/WeChat/Email/SMS alarm messages, etc.) automatically in real time according to the status of the air quality by the pre-set edge computing mechanism (IF-THEN-ELSE logic rules). After IoTstar receives the air quality information sent by WISE, it can provide services such as: "Controller Remote Access Service", "Sensor Data Collection Service", "Sensor Data Visualization Service", "Sensor Data Report Service" and "Bot Service with Mobile Phone" services, and help users quickly build a Cloud-based air quality monitoring system.

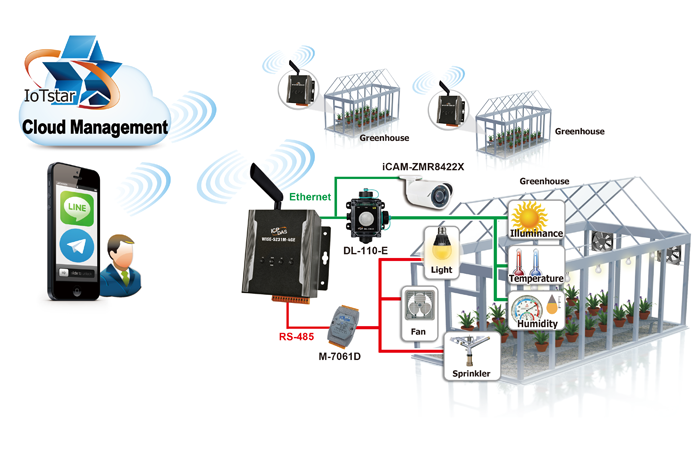

Cloud-based Greenhouse Monitoring Application

In the development trend of agricultural refinement and technology, intelligent greenhouse planting has always played an important role. The ICP DAS "IoTstar+WISE+DL module" solution work as an automated intelligent greenhouse monitoring system, it can perform real-time cloud monitoring of illuminance/temperature/humidity for the greenhouse, and automatically execute the corresponding scheduled tasks (such as: turning on the air conditioner, adjusting lighting, activating sprinklers, fertilizing etc.), or send LINE/Telegram/WeChat/Email/SMS alarm messages to related personnel to take immediate actions in response to abnormal status notification. WISE can also connect to ICP DAS iCAM series IP cameras to perform real-time video monitoring of the greenhouse. When an unusual intrusion is detected, WISE will automatically send text and video messages to the security personnel through LINE/Telegram/WeChat to take immediate actions. In addition, with the services provided by IoTstar such as "Controller Remote Access Service", "Sensor Data Collection Service", "Sensor Data Visualization Service", "Sensor Data Report Service" and "Bot Service with Mobile Phone", user can easily build a cloud-based greenhouse monitoring system to grasp the environmental status of each greenhouse anytime, anywhere and take actions accordingly, so as to move towards the era of intelligent agriculture with high efficiency, high productivity, safety and low operating risks.

Cloud-based Building, Warehouse, Factory Monitoring Application

Using ICP DAS "IoTstar+WISE+iSN/DL/CL module" solution, it can help enterprises quickly establish a Cloud-based monitoring system for Building, Warehouse, and Factory facilities. The iSN modules can assist in the detection of liquid leakage, and the DL modules can measure the temperature and humidity data of the environment. After the iSN and DL modules transmit the measured data to the WISE IIoT edge controller for sorting and recording, WISE can transmit the collected data to IoTstar, and perform the preset edge computing mechanism (IF -THEN-ELSE logic rules), and then automatically take real-time actions in response to status of liquid leakage/ temperature/humidity in the environment(such: turn on the exhaust fan, turn on the warning light). It can also send LINE/Telegram/WeChat/Email/SMS alarm messages to related personnel for the unusual status notification, and work as an automated intelligent warehouse monitoring system. WISE can also connect with ICP DAS iCAM series IP cameras to perform real-time video monitoring of the warehouse. When an unusual intrusion is detected, WISE will automatically send text and video messages to the security personnel through LINE/Telegram/WeChat, to take immediate actions. In addition, with the services provided by IoTstar such as "Controller Remote Access Service", "Sensor Data Collection Service", "Sensor Data Visualization Service", "Sensor Data Report Service" and "Bot Service with Mobile Phone", user can easily build a cloud-based warehouse monitoring system to grasp the environmental suatus of each warehouse anytime, anywhere and take actions accordingly.

Cloud-based Monitoring Application for Traditional Devices

Using ICP DAS "IoTstar+WISE+tGW module" solution, it can assist users to quickly build an Cloud-based IoT monitoring system for traditional devices that cannot connect to Network. Users can use tGW-700(Modbus RTU/ASCII to TCP converter) to connect to traditional devices via RS- 485 interface, and convert the Modbus RTU/ASCII protocol on the traditional devices to Modbus TCP protocol, and the device status can be sent to WISE IIoT edge controller through Ethernet for data sorting and recording, and then send back to IoTstar to quickly build the cloud-based IoT monitoring system for the traditional equipment.

Take the traditional vending machines that are common on the street as an example, for these device lack the networking capability, the replenishment and equipment maintenance operations usually need to rely on inspection (replenishment) personnel to check regularly according to a fixed route. It is time-consuming, labor-intensive and causes additional cost. Through the solution provided by ICP DAS, information such as inventory and device status in the vending machine can be sent to the headquarter in real time for statistical analysis, and headquarter can timely dispatch the inspection (replenishment) personnel to the vending machine in need to adjust the device status of the vending machine so that the burden of inspection (replenishment) personnel can be reduced and then the manpower and transportation costs can be saved.

Registration & Getting IoTstar (Basic Version)

Function Comparison Table

| Version | Function | |||||

|---|---|---|---|---|---|---|

| Controller Remote Access Service |

Sensor Data Collection Service |

Sensor Data Visualization Service |

Sensor Data Report Service |

Bot Service with Mobile Phone |

||

| IoTstar | Yes | Yes(Note 1) | Yes (*All require additional purchase) |

|||

| IoTstar 2025 | Yes(Note 2) (Built-in, no additional purchase necessary) |

|||||

| Note 1:

Three versions of IoTstar 2025 are offered, tailored for MS SQL, MySQL or Oracle, so users can choose the version that aligns with their database preferences.

Note 2: For the "Sensor Data Visualization Service-Dashboard Service", the "Alarm Event" function has been added, and the operation of other widgets has been optimized. For the "Sensor Data Report Service ", the “Time Range setting” function has been added.

|

||||||

Installation Platform Requirement

| Specification Suggestions | |

|---|---|

| CPU | 64-bit (x64); 3.0 GHz or higher GHz Processor |

| RAM & Hard Disk space |

|

| OS System | Windows 7, Windows 8, Windows 10, Windows Server 2012 or later OS system (64-bit Windows required). |

| .NET Framework required | Microsoft .NET Framework 4.5 or later installed. |

| Notes: IoTstar needs to work with the IIS Web Server and Database system.

|

|

|

|

|

|

IoTstar 2025 Selection Guide

|

|

| Model | Description |

|---|---|

| IoTstar2025-RC050 | IoTstar 2025 - IoT Cloud Management Software (Maximum 50 controllers can be connected.) |

| IoTstar2025-RC200 | IoTstar 2025 - IoT Cloud Management Software (Maximum 200 controllers can be connected.) |

| IoTstar2025-RC500 | IoTstar 2025 - IoT Cloud Management Software (Maximum 500 controllers can be connected.) |

| IoTstar2025-UC050-200 | IoTstar 2025 Upgrade Package (Upgrade the maximum number of controllers connected to IoTstar from 50 to 200.) |

| IoTstar2025-UC200-500 | IoTstar 2025 Upgrade Package (Upgrade the maximum number of controllers connected to IoTstar from 200 to 500.) |

| Note: For IoTstar versions released before 2025, no new features will be added. However, essential bug fixes will continue to be provided. If you need to expand the number of controllers or purchase additional software features, please contact our sales team. | |